Virginia Metal Roofers

Hampton Roads Metal Roofers

Call now 757-210-6580

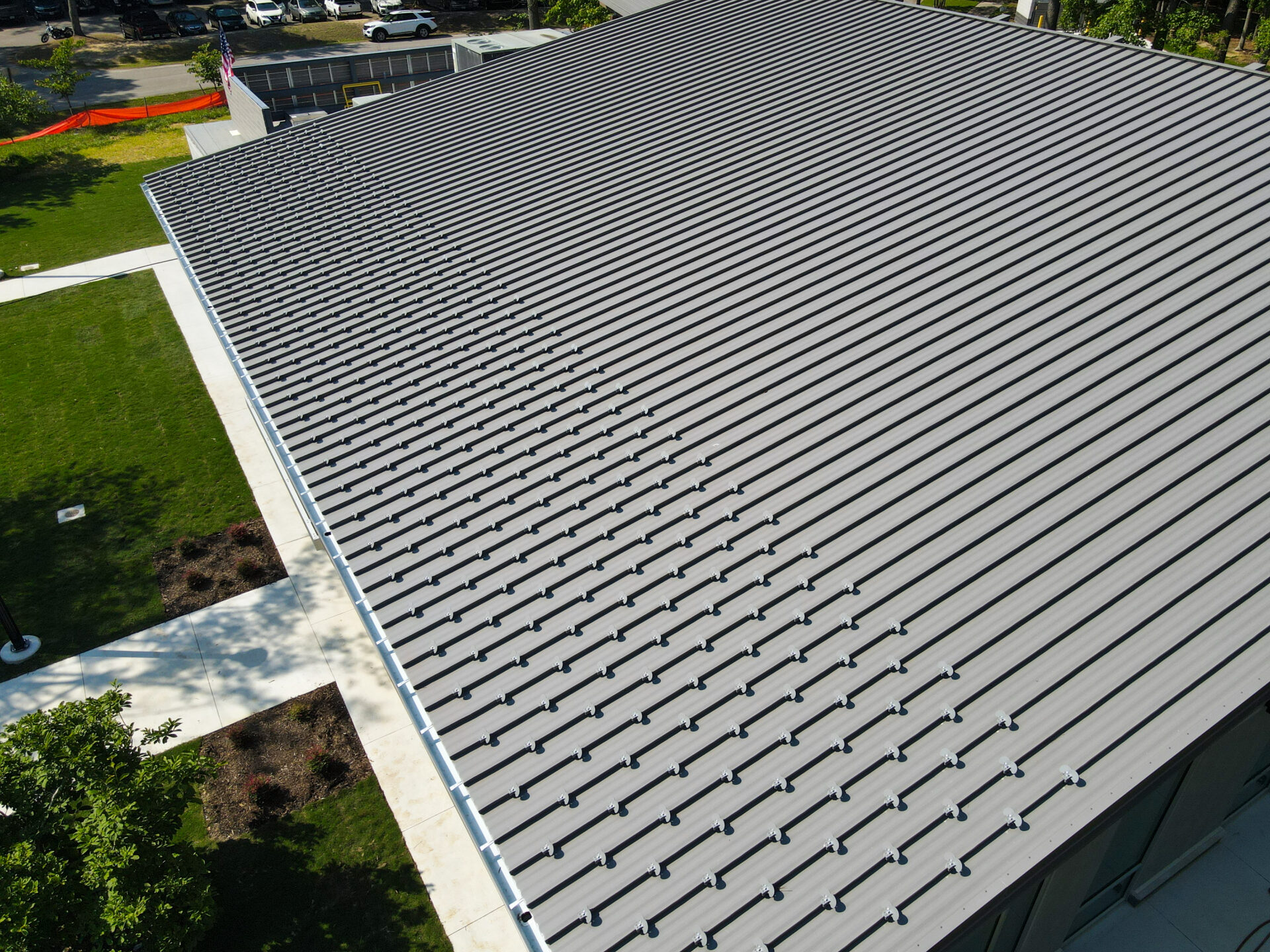

Experience the Best Standing Seam Metal Roofing in Hampton Roads with Seaboard Construction

When it comes to top-quality metal roofing in Hampton Roads, look no further than Seaboard Construction. Our commitment to customer satisfaction and craftsmanship sets us apart from other roofing companies in the Norfolk, Chesapeake, Virginia Beach, and Newport News areas.

What makes us different? We take pride in fabricating and forming our own metal panels in-house. This ensures the highest level of precision and excellence in every panel. Our experienced team pays meticulous attention to detail, guaranteeing installations that meet the highest standards.

As a local company, we understand the unique needs and challenges of the Hampton Roads area. Our professionalism, reliability, and exceptional customer service have earned us a strong reputation. When you choose Seaboard Construction, you can trust that your metal roof will be installed with care and expertise.

To prioritize your satisfaction, we offer a comprehensive 2-year craftsmanship warranty on all installed metal roofs. This guarantee gives you peace of mind, knowing that any defects or issues arising from our workmanship will be promptly addressed.

Ready to experience the excellence and satisfaction that sets Seaboard Construction apart? Contact us today to discuss your project and discover how we can meet your metal roofing needs in Hampton Roads.

Reach out to our team of metal roofing contractors today for a free roof inspection!

Seaboard Construction is a Class A Certificated contractor specializeing in commercial and residential roofing solutions in Hampton Roads.

Our Metal Roof Gallery

Call 757-210-6580

Top 5 Reasons Metal Roofs Leak (How to Prevent Leaks!)

In this article we’ll review the best option for your metal roof underlayment:

-

Underlayment’s Crucial Role: Underlayment acts as a safeguard between the roof deck and metal panels, enhancing weather resistance and preventing leaks for a longer-lasting metal roof.

-

Types and Functions: Different underlayment materials include synthetic (lightweight, tear-resistant), felt (moderate moisture resistance), and rubberized asphalt (flexible, self-sealing). Each provides specific benefits like UV resistance and insulation.

-

Choosing the Right Underlayment: Climate, roof slope, and design influence underlayment selection. For instance, waterproof options are vital in rainy regions. Energy efficiency is boosted with insulating underlayments.

-

Metal Roof Advantages: Metal roofs endure extreme weather, reflect heat for energy savings, and offer versatile design options.

-

Importance and Benefits: Underlayment shields against elements, acts as insulation, controls noise, and minimizes condensation, adding to roof longevity.

-

Underlayment Types: Synthetic underlayment (lightweight, UV-resistant), felt underlayment (traditional, moisture-resistant), and rubberized asphalt underlayment (flexible, self-sealing).

-

Considerations for Various Materials: Asphalt shingles, clay/concrete tiles, and wood shakes/shingles all benefit from underlayment tailored to their needs.

-

Rubberized Underlayment: Ideal for metal roofs due to weather resistance, thermal benefits, and noise reduction.

-

Advantages with Proper Underlayment: Metal roofs with rubberized underlayment ensure weather protection, energy efficiency, and noise reduction, making them a durable and comfortable choice.

Importance of underlayment in a metal roof system:

Underlayment plays a crucial role in the overall performance and longevity of a metal roof system. It acts as a secondary layer of protection between the roof deck and the metal panels, providing added waterproofing and insulation. The underlayment helps to prevent water infiltration, reduce the risk of leaks, and enhance the overall weather resistance of the roof. Choosing the right underlayment is essential to ensure the long-term durability and performance of the metal roof, making it a critical decision for homeowners and roofing professionals.

Overview of underlayment materials and their functions:

There are various types of underlayment materials available for metal roofs, each with its specific functions and benefits. Common options include synthetic underlayment, felt underlayment, and rubberized asphalt underlayment. Synthetic underlayment is known for its lightweight, tear-resistant, and waterproof properties. Felt underlayment, also known as roofing felt or tar paper, is a traditional option that provides moderate moisture resistance and acts as a protective barrier. Rubberized asphalt underlayment offers superior flexibility, self-sealing capabilities, and enhanced protection against water intrusion. Understanding the different materials and their functions will help homeowners make an informed decision about the most suitable underlayment for their standing seam metal roof.

Choosing the right underlayment for a metal roof: “What do you put under a standing seam metal roof?”

Choosing the right underlayment for a standing seam metal roof is crucial to ensure optimal performance and protection. There are several factors to consider when determining the appropriate underlayment for your metal roof. One key consideration is the climate in which the roof will be installed. For example, in areas like Hampton Roads with high rainfall, a waterproof underlayment is essential to prevent water infiltration and potential leaks. Additionally, the slope of the roof and the overall design of the roofing system should be taken into account when selecting underlayment materials. A standing seam metal roof typically requires an underlayment that is compatible with the roof’s vertical profile and can accommodate the metal panels’ attachment.

Another consideration is the expected lifespan of the metal roof. Some underlayment materials offer greater durability and longevity, which can enhance the overall lifespan of the roof system. Additionally, the underlayment should provide sufficient insulation and energy efficiency properties to improve the overall energy performance of the building. This is particularly important in climates with extreme temperatures, where proper insulation can help reduce heating and cooling costs.

Understanding Metal Roofs and Their Benefits

An overview of metal roofs:

Metal roofs are roofing systems made from various metals, such as steel, aluminum, or copper. They consist of metal panels or shingles that are installed on the roof deck to provide protection against the elements. Metal roofs are known for their durability, weather resistance, and longevity. They can withstand harsh weather conditions, including high winds, heavy rain, snow, and even hail. Metal roofs are available in various styles, including standing seam, corrugated, and metal shingles, offering homeowners a range of design options to suit their aesthetic preferences.

Advantages of metal roofs over other roofing materials:

Durability and longevity: Metal roofs are renowned for their exceptional durability and long lifespan. Unlike other roofing materials that may deteriorate over time, metal roofs can last 50 years or more with proper installation and maintenance. They are resistant to corrosion, warping, and shrinking, and can withstand extreme weather conditions without compromising their integrity.

Energy efficiency and environmental sustainability:

Metal roofs are highly energy-efficient, reflecting solar heat and reducing the need for air conditioning during hot summers. They have high emissivity, allowing them to release heat quickly, which further contributes to energy savings. Additionally, metal roofs are often made from recycled materials and are themselves recyclable at the end of their lifespan, making them a sustainable choice for environmentally-conscious homeowners.

Design versatility and aesthetic appeal:

Metal roofs offer a wide range of design options and finishes, allowing homeowners to achieve the desired look for their homes. They come in various colors, textures, and profiles, such as standing seam, ribbed panels, or metal shingles, providing versatility to match different architectural styles. Whether a homeowner seeks a modern, sleek appearance or a more traditional aesthetic, metal roofs can be customized to suit their preferences.

Overall, metal roofs provide numerous advantages over other roofing materials, making them a popular choice for homeowners seeking durability, energy efficiency, and aesthetic appeal in their roofing system.

The Purpose and Importance of Underlayment

Role of underlayment in a metal roof system:

Underlayment refers to the layer of material installed between the roof deck and the metal panels in a metal roof system. Its primary function is to provide an additional layer of protection against weather elements, enhance the roof’s performance, and prolong its lifespan. The underlayment acts as a secondary barrier to prevent water infiltration and protects the roof deck from moisture damage. It also serves as a thermal insulator, reducing heat transfer and improving energy efficiency. By understanding the definition and role of underlayment, homeowners can appreciate its significance in ensuring the long-term performance of their metal roof system.

Functions of underlayment:

Weather protection and moisture resistance: Underlayment acts as a waterproofing layer, safeguarding the roof deck and interior of the building from water intrusion caused by rain, snow, or ice dams. It prevents moisture from seeping into the roof structure and causing damage, such as rot, mold, or decay. The underlayment also acts as a barrier against wind-driven rain, protecting vulnerable areas of the roof.

Thermal insulation and energy efficiency:

Underlayment provides an additional layer of insulation, reducing heat transfer and improving energy efficiency. It helps to keep the building cool in hot weather by reflecting solar heat, reducing the load on the air conditioning system. In colder climates, underlayment can also help prevent heat loss, enhancing the building’s overall thermal performance.

Sound reduction and condensation control:

Underlayment helps to dampen sound transmission, reducing noise from rain, hail, or other external sources. Additionally, it can assist in controlling condensation by providing a moisture barrier and allowing proper ventilation within the roof system. This helps to prevent the buildup of excess moisture, which can lead to issues such as rot, mildew, or corrosion.

By understanding the functions of underlayment, homeowners can appreciate its role in providing essential protection, insulation, and control measures in their metal roof systems.

Types of Underlayment for Metal Roofs

Synthetic underlayment:

Composition and benefits:

Synthetic underlayment is typically made of polyester or polypropylene materials. It offers excellent tear resistance, durability, and waterproofing properties. Synthetic underlayment is lightweight, making it easier to handle during installation. It also provides superior UV resistance, protecting the roof from potential damage caused by prolonged sun exposure. Additionally, synthetic underlayment has a non-skid surface, ensuring safe footing for installers during the roofing process.

Installation considerations and compatibility with metal roofs:

Synthetic underlayment is compatible with various metal roofing systems, including standing seam and corrugated panels (we won’t typically install corrugated panels unless they are wall panels on a commercial building). It can be installed using roofing nails or cap nails, depending on the specific requirements of the roofing system. Synthetic underlayment is often designed with a slip-resistant surface, allowing installers to work more safely on the roof. Its lightweight nature makes it easier to handle and maneuver during installation.

Felt underlayment:

Characteristics and advantages:

Felt underlayment, rarely used in modern metal roof installation, also known as roofing felt or tar paper, is a traditional option for underlayment. It is made from asphalt-impregnated cellulose or fiberglass, providing moderate moisture resistance and protection. Felt underlayment offers good tear resistance and acts as a protective barrier against potential leaks. It is also commonly used as a temporary waterproofing layer during roof construction.

Applicability to different metal roofing systems:

Felt underlayment is compatible with various types of metal roofing systems, including standing seam, corrugated, and metal shingles. It can be installed by overlapping the rolls and securing them to the roof deck using nails or staples. Felt underlayment provides an additional layer of waterproofing, offering protection against water infiltration and potential leaks.

Rubberized asphalt underlayment:

Features and advantages:

Rubberized asphalt underlayment is a self-adhering, self-sealing, rubberized material that offers excellent flexibility and protection against moisture penetration. It consists of a rubberized asphalt compound reinforced with a polyester or fiberglass mat. rubberized asphalt underlayment provides superior waterproofing properties, conforming to irregular roof surfaces and sealing around fasteners.

Suitable applications and limitations:

Rubberized asphalt underlayment is commonly used in areas with a higher risk of water intrusion, such as valleys, eaves, and roof penetrations. Rubberized asphalt underlayment is self adhering; we will almost never put a nail through a rubberized asphalt underlayment when fastening to the roof deck. However, due to its self-sealing properties, it is essential to follow the manufacturer’s guidelines for proper installation to ensure effective sealing and waterproofing.

Pro tip: rubberized asphalt (known as an “ice and water shield”) should always be used on a roof deck of the roof pitch is less than 3/12. Many metal roofing contractors will use a synthetic underlayment in this instance, but this is not best practice for metal roof installation.

Comparing underlayment options for metal roofs:

Durability and resistance to moisture penetration:

Synthetic underlayment and rubberized asphalt underlayment provide excellent durability and resistance to moisture penetration. They offer superior waterproofing properties compared to felt underlayment, which may be more susceptible to water damage.

Thermal performance and energy efficiency:

Synthetic underlayment often has better thermal performance and energy efficiency properties compared to felt underlayment. Synthetic materials provide better insulation, reducing heat transfer and improving overall energy efficiency.

Sound absorption and condensation control:

Rubberized asphalt underlayment offers better sound absorption properties compared to synthetic underlayment. They can help reduce noise from rain, hail, or other external sources. Rubberized asphalt underlayment also helps control condensation by providing a moisture barrier and allowing proper ventilation within the roof system.

A felt underlayment is almost never used in modern metal roofing installations, and is not used or recommended by Seaboard Construction.

By comparing the characteristics and advantages of different underlayment options for metal roofs, homeowners can make an informed decision based on their specific needs and requirements.

Call now 757-210-6580

Metal Roofers in Hampton Roads

Trusted Metal Roofing Company

Underlayment Considerations for Different Roofing Materials

Asphalt shingles:

Recommended underlayment options for metal roofs:

When installing an underlayment for asphalt shingles, it is recommended to use a high-quality synthetic underlayment (with the exception of valleys, eaves, pitches less than 3/12, and around penetrations such as plumbing pipes and vents – for this we always will use rubberized asphalt). Synthetic underlayment offers superior waterproofing properties, durability, and resistance to moisture. It provides an effective barrier against potential leaks and acts as an additional layer of protection for the roof deck. Additionally, synthetic underlayment offers better thermal performance and energy efficiency compared to traditional felt underlayment.

Comparing underlayment requirements with other roofing materials:

Metal roofs typically have similar underlayment requirements as asphalt shingles. However, metal roofs often require a more robust underlayment due to their longer lifespan and potential for extreme weather exposure. Both asphalt shingles and metal roofs can utilize synthetic underlayments.

Clay and concrete tiles:

Underlayment considerations specific to tile roofs:

For tile roofs, it is crucial to choose an underlayment that offers excellent waterproofing properties and is compatible with the specific type of tile being installed. Synthetic or rubberized underlayments are commonly used for tile roofs, providing a layer of protection against potential leaks.

Contrasting underlayment needs with metal roofs:

Metal roofs have different underlayment needs compared to tile roofs. While both roofing materials require proper waterproofing, metal roofs benefit from underlayment options that offer better thermal insulation and energy efficiency. Rubberized, with its superior thermal performance, is a suitable choice for metal roofs as it helps reduce heat transfer and improve overall energy efficiency. Additionally, Rubberized underlayment provides better resistance to moisture penetration, ensuring the long-term durability of metal roofs.

Wood shakes and shingles:

Underlayment choices for wood roofs:

Wood shakes and shingles often require a layer of synthetic or rubberized underlayment to provide protection against water infiltration and potential leaks. These underlayment options are compatible with wood roofs, offering a reliable moisture barrier.

Advantages of specific underlayment for metal roofs:

Metal roofs can benefit from synthetic or rubberized asphalt underlayment, even when installed over wood shakes or shingles. Synthetic underlayment provides better thermal insulation and energy efficiency, which is advantageous for metal roofs. Rubberized asphalt underlayment, with its superior waterproofing properties, ensures effective moisture protection and can further enhance the longevity and durability of the metal roof system.

Choosing Underlayment for Metal Roofs: Rubberized is the Best Choice

Climate and weather conditions:

The climate and weather patterns of the region where the metal roof will be installed play a significant role in selecting the appropriate underlayment. In areas with high precipitation or extreme weather conditions, such as heavy rain, snow, or strong winds, it is crucial to choose an underlayment with excellent waterproofing capabilities and resistance to moisture infiltration. Additionally, underlayments that offer superior UV resistance and weatherproofing properties are ideal for regions with hot and sunny climates. Considering the climate and weather conditions will ensure the underlayment effectively protects the metal roof from potential leaks and damage.

Roof slope and pitch:

The slope and pitch of the roof affect how water drains off the surface. Steeper roofs typically shed water more efficiently, reducing the risk of leaks. For roofs with a low slope or pitch, it is crucial to select an underlayment that provides enhanced water resistance and drainage capabilities to prevent water pooling and potential leaks. In these cases, a self-adhering underlayment or a rubberized asphalt underlayment may be recommended to ensure proper water shedding and moisture protection.

Local building codes and regulations:

Local building codes and regulations may specify certain requirements for underlayment materials and installation methods. It is important to consult with local authorities or building professionals to ensure compliance with these codes. They may have specific guidelines regarding fire resistance, moisture barriers, or other factors that need to be considered when choosing underlayment for metal roofs. Adhering to these regulations ensures the structural integrity and safety of the roof system.

Considering these factors when choosing underlayment for metal roofs will help ensure the selection of the right underlayment material and installation method, providing optimal protection, performance, and longevity for the metal roof system. Consulting with roofing professionals or manufacturers can provide valuable guidance and assistance in making the best choice for underlayment based on the specific needs and requirements of the project.

Advantages of Metal Roofs with the Right Underlayment

Enhanced weather resistance and moisture protection:

Metal roofs, when paired with a rubberized underlayment, offer exceptional weather resistance and moisture protection. The rubberized underlayment acts as an additional barrier against water infiltration, preventing leaks and potential damage to the roof deck and interior of the structure. By effectively sealing out moisture, the rubberized underlayment helps maintain the integrity of the metal roof system, ensuring its durability and longevity. It provides peace of mind, especially in regions prone to heavy rainfall, snow, or high humidity levels, where effective moisture protection is crucial.

Improved thermal performance and energy efficiency:

Rubberized underlayment for metal roofs can contribute to improved thermal performance and energy efficiency. Rubberized underlayments with enhanced insulation properties help reduce heat transfer and minimize energy loss through the roof. By creating a thermal barrier, the rubberized underlayment helps regulate the temperature inside the building, reducing the need for excessive heating or cooling. This leads to energy savings and increased comfort for the occupants.

Noise reduction and condensation control:

Metal roofs, especially in areas with heavy rainfall or hailstorms, can generate more noise compared to other roofing materials. However, a rubberized underlayment can help reduce the noise levels by providing an additional layer of insulation and sound absorption. The rubberized underlayment acts as a buffer, reducing the impact of rain, hail, and other external noises, resulting in a quieter indoor environment. Additionally, the rubberized underlayment plays a crucial role in condensation control. It helps prevent condensation buildup by creating a moisture barrier and promoting proper ventilation. This helps minimize the risk of moisture-related issues, such as mold and mildew growth, which can affect the structural integrity and indoor air quality of the building.

That’s a Wrap: Standing Seam Metal Roof Underlayments

The importance of underlayment in metal roof systems:

Rubberized underlayment plays a critical role in the performance and longevity of metal roof systems. It acts as a protective layer, providing weather resistance, moisture control, thermal insulation, and sound reduction. The right underlayment ensures the integrity of the roof by preventing leaks and minimizing potential damage. It enhances the overall functionality and durability of the metal roof, offering long-lasting protection for the structure.

Call now 757-210-6580

Schedule A Roof Inspection

Call 757-210-6580 or fill out our form

Licensed & Insured Class A Contractor

Hours & Address

Hours

MONDAY – SUNDAY

7:00am – 6:00pm